Polymers & Plastics

VUP offers building blocks and stabilizers for polymers, enhancing durability and processing with advanced R&D support.

Key Applications

Polymer Stabilization (Light, Heat, Oxidation)

Protecting polymers from degradation caused by UV light, heat, and oxidation is crucial for extending product lifespan and maintaining performance, especially in demanding applications.

Controlled Polymerization & Architecture

Achieving specific polymer properties often requires precise control over molecular weight, polydispersity, and architecture during synthesis.

Polyurethane Building Blocks

Formulating high-performance polyurethanes (dispersions, elastomers, adhesives) requires specific intermediates to impart desired properties like water dispersibility, flexibility, and adhesion.

Crosslinking & Property Enhancement

Improving the mechanical strength, thermal stability, elasticity, and chemical resistance of polymers often involves creating crosslinked networks within the material.

Industry Challenges

Discover the unique challenges faced by Polymers & Plastics and how VUP Solutions can help overcome them.

Polymer Stabilization (Light, Heat, Oxidation)

Challenge:

Protecting polymers from degradation caused by UV light, heat, and oxidation is crucial for extending product lifespan and maintaining performance, especially in demanding applications.

VUP Solutions:

We offer Hindered Amines, including Hindered Amine Light Stabilizers (HALS) derived from our TAA production line. These additives act as potent radical scavengers, significantly inhibiting polymer degradation, preventing cracking and discoloration, and improving the long-term durability of plastics and coatings. Our TEMPO derivatives also contribute to polymer stability.

Relevant Services

View all services

Research & Development

VUP's R&D division solves complex chemistry challenges across diverse industries.With 70+ years of chemical expertise, we transform ideas into viable technological solutions tailored to your needs.

Accreditations

Accredited Analytical, Technical-Safety & Environmental Services

The ATBEL (Analytical, Technical-Safety, and Environmental Laboratories) division is a specialized testing center within VUP, a.s., providing expert analytical services to both internal R&D projects and external partners. We deliver reliable, accredited results under SNAS Certificate No. S-118 (ISO/IEC 17025) and ISO 9001, ensuring the highest standards of quality and precision. Our services are led by division head Ing. Ľudovít Žiak, PhD.

Accreditations

Controlled Polymerization & Architecture

Challenge:

Achieving specific polymer properties often requires precise control over molecular weight, polydispersity, and architecture during synthesis.

VUP Solutions:

TEMPO (CAS 2564-83-2) functions as a highly effective mediator in Nitroxide-Mediated Polymerization (NMP), allowing for the synthesis of polymers with well-defined structures. This control enables the development of materials with enhanced performance characteristics tailored for specific applications. H-TEMPO (CAS 2226-96-2) can serve as a polymerization inhibitor for process control or storage.

Relevant Products

View all products

TEMPO (2,2,6,6-Tetramethylpiperidin-1-oxyl)

A highly versatile and stable nitroxyl radical, renowned for its utility as a catalyst in selective organic oxidations and as a mediator in controlled radical polymerization (NMP). VUP produces high-purity TEMPO at pilot scale.

Key Properties

4-Hydroxy-TEMPO (TEMPOL / H-TEMPO)

A key functionalized derivative of TEMPO featuring both a stable nitroxyl radical and reactive hydroxyl group. Serves as a versatile antioxidant, catalyst, spin label, and crucial intermediate for synthesizing specialty chemicals.

Key Properties

Relevant Services

View all servicesPolyurethane Building Blocks

Challenge:

Formulating high-performance polyurethanes (dispersions, elastomers, adhesives) requires specific intermediates to impart desired properties like water dispersibility, flexibility, and adhesion.

VUP Solutions:

We provide key methylolalkanoic acids DMPA (CAS 4767-03-7) and DMBA (CAS 10097-02-6), essential for creating stable waterborne PUDs with enhanced performance. HPVA serves as an intermediate for durable polyester and polyurethane resins. O,O'-Bis(3-aminopropyl)polyethyleneglycol can be used as a reactive component to impart flexibility and hydrophilicity.

Relevant Products

View all products

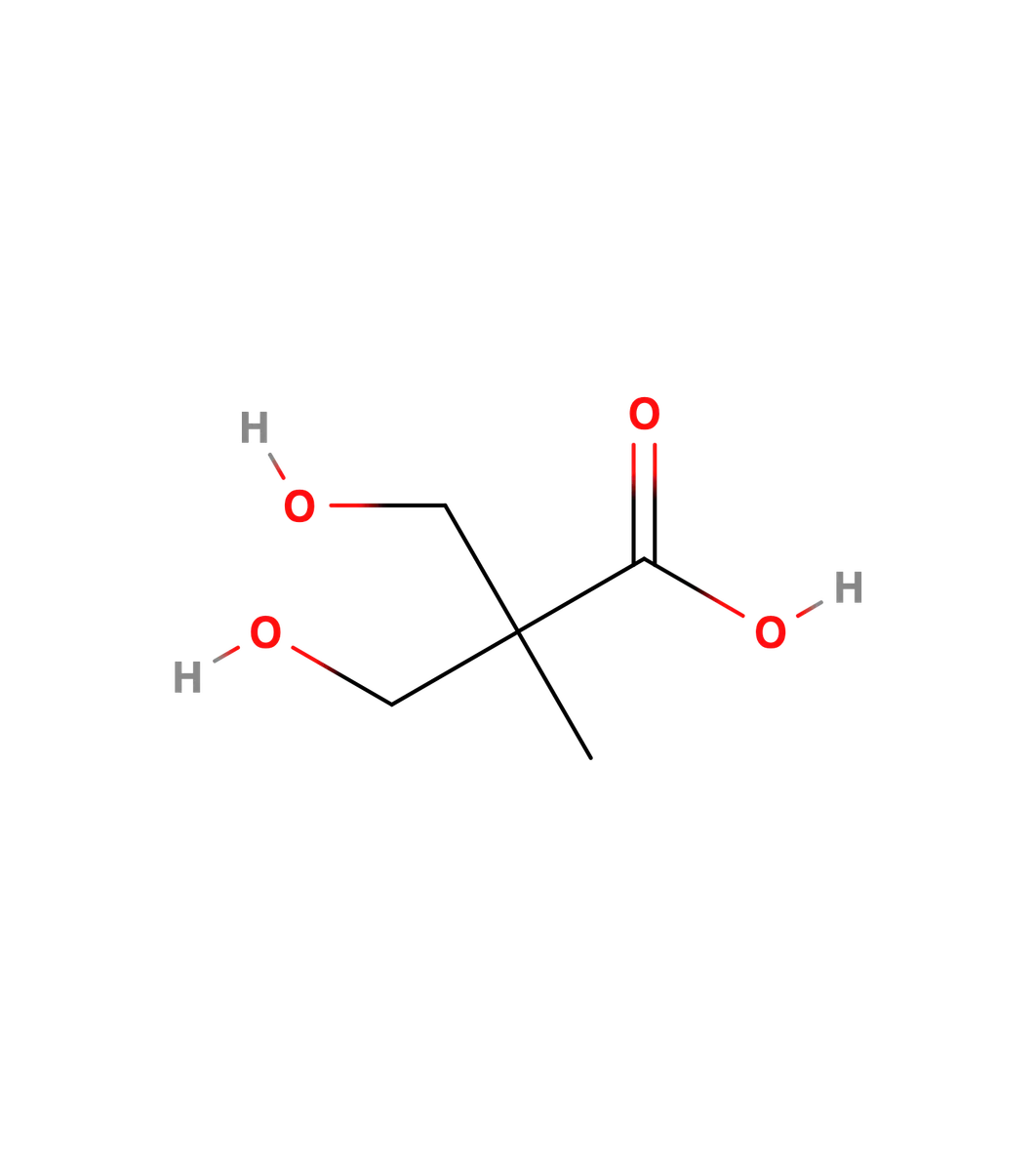

Dimethylolbutyric Acid (DMBA)

An advanced trifunctional intermediate enabling next-generation waterborne resins. Facilitates solvent-free PUD synthesis with lower processing temperature and enhanced film resistance.

Key Properties

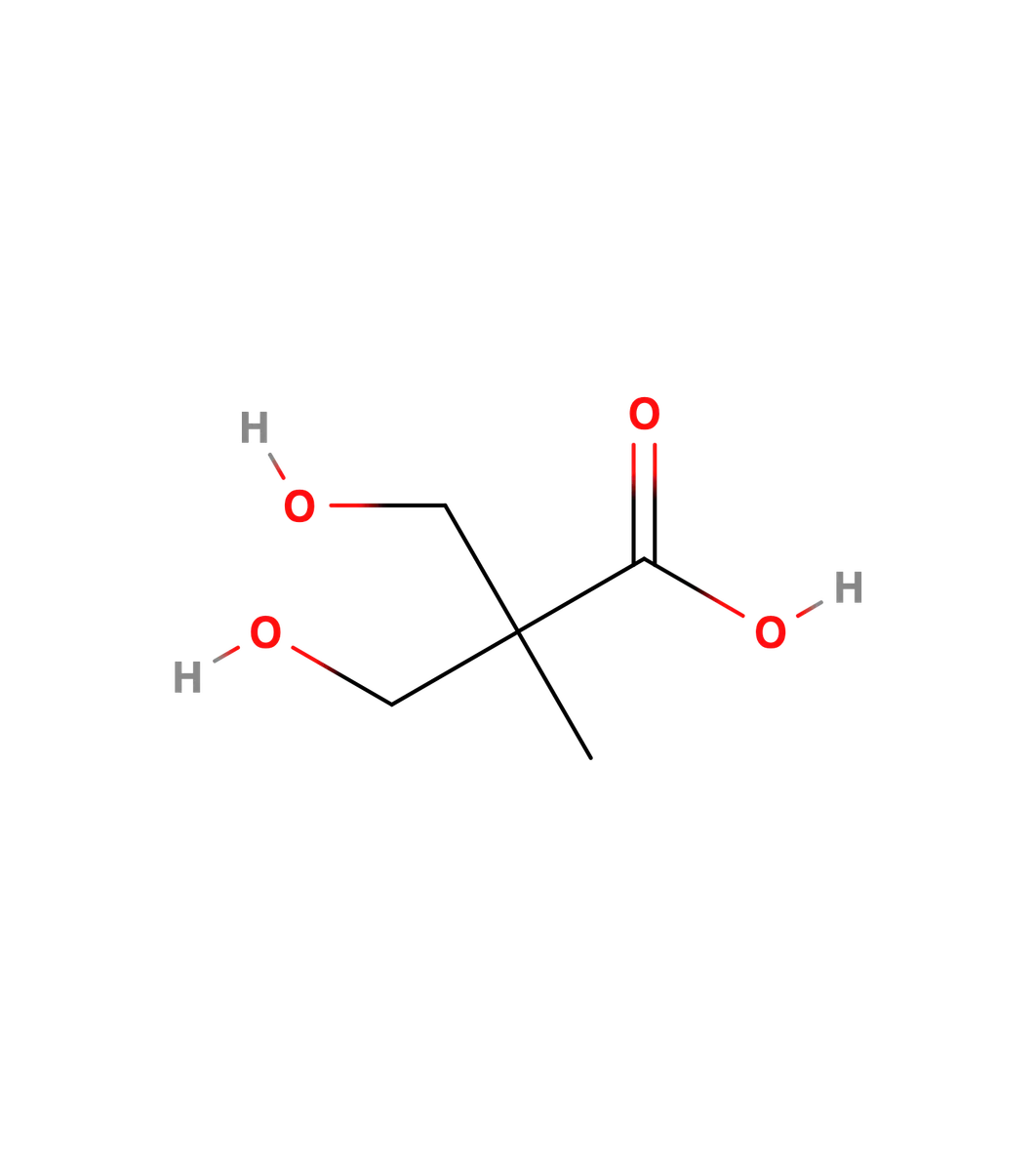

Dimethylolpropionic Acid (DMPA)

Essential trifunctional intermediate enabling high-performance waterborne coatings, polyurethane dispersions, alkyds, and polyesters with superior stability and environmental benefits.

Key Properties

3-Hydroxypivalic Acid (HPVA)

A unique hydroxy acid featuring a neopentyl structure, essential for synthesizing high-performance polyesters and esters with exceptional hydrolytic stability, thermal stability, and weather resistance.

Key Properties

Relevant Services

View all servicesCrosslinking & Property Enhancement

Challenge:

Improving the mechanical strength, thermal stability, elasticity, and chemical resistance of polymers often involves creating crosslinked networks within the material.

VUP Solutions:

We offer crosslinking agents such as Adipic acid dihydrazide. These multifunctional molecules react with polymer chains to enhance structural integrity and performance characteristics critical for demanding applications in adhesives, coatings, elastomers, and plastics.

Relevant Services

View all services

Research & Development

VUP's R&D division solves complex chemistry challenges across diverse industries.With 70+ years of chemical expertise, we transform ideas into viable technological solutions tailored to your needs.

Accreditations

Accredited Analytical, Technical-Safety & Environmental Services

The ATBEL (Analytical, Technical-Safety, and Environmental Laboratories) division is a specialized testing center within VUP, a.s., providing expert analytical services to both internal R&D projects and external partners. We deliver reliable, accredited results under SNAS Certificate No. S-118 (ISO/IEC 17025) and ISO 9001, ensuring the highest standards of quality and precision. Our services are led by division head Ing. Ľudovít Žiak, PhD.

Accreditations

Featured VUP Products

Explore our core portfolio of chemical intermediates and solutions for this industry

TEMPO (2,2,6,6-Tetramethylpiperidin-1-oxyl)

A highly versatile and stable nitroxyl radical, renowned for its utility as a catalyst in selective organic oxidations and as a mediator in controlled radical polymerization (NMP). VUP produces high-purity TEMPO at pilot scale.

Key Properties

4-Hydroxy-TEMPO (TEMPOL / H-TEMPO)

A key functionalized derivative of TEMPO featuring both a stable nitroxyl radical and reactive hydroxyl group. Serves as a versatile antioxidant, catalyst, spin label, and crucial intermediate for synthesizing specialty chemicals.

Key Properties

Dimethylolbutyric Acid (DMBA)

An advanced trifunctional intermediate enabling next-generation waterborne resins. Facilitates solvent-free PUD synthesis with lower processing temperature and enhanced film resistance.

Key Properties

Dimethylolpropionic Acid (DMPA)

Essential trifunctional intermediate enabling high-performance waterborne coatings, polyurethane dispersions, alkyds, and polyesters with superior stability and environmental benefits.

Key Properties

3-Hydroxypivalic Acid (HPVA)

A unique hydroxy acid featuring a neopentyl structure, essential for synthesizing high-performance polyesters and esters with exceptional hydrolytic stability, thermal stability, and weather resistance.